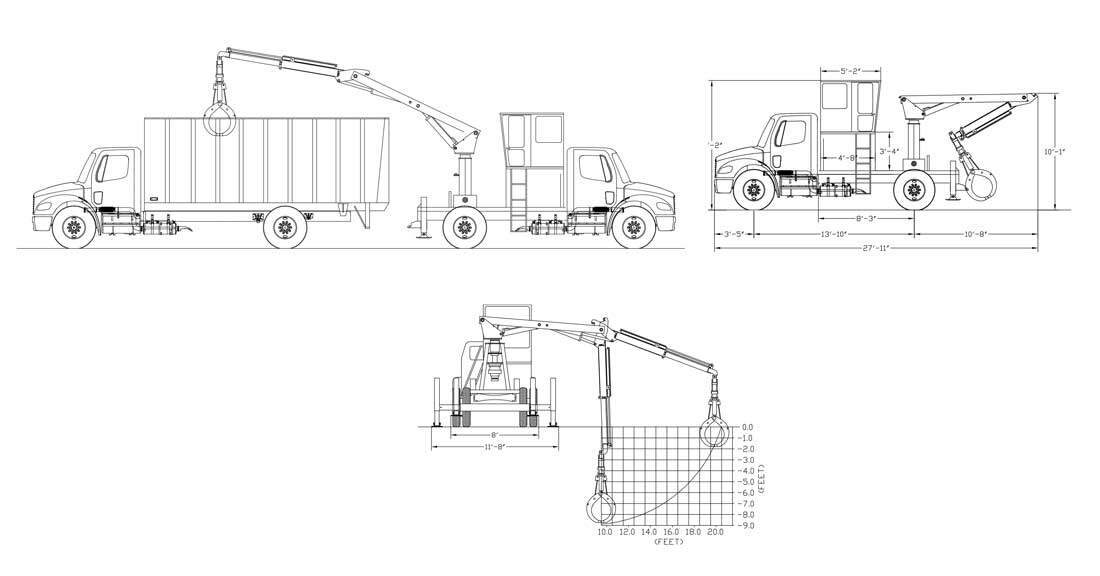

RS3 Rear Steer Lightning Loader

The Most Advanced and Efficient System for Route Collection

This Grapple Loader is a great system for high volume route collection. The most advanced and efficient system for collecting trash on the market. The two features that set this unit apart is the ability to drive in reverse from the operator’s station and not needing outriggers for most loading operations. The Lightning Rear Steer® drives behind, and loads into separate haul trucks from a single lane. To learn more about the Lightning Rear Steer®, click on the “Videos” tab below.

Petersen Industries RS3 Rear Steer Loader Advantages

Total Control

- Twin mechanical joystick controls

- Operator cab has air-conditioning, heat, air-ride seat and windshield wipers

- Operator cab also features all normal driving controls for driving backwards; brakes, acceleration, horn, etc.

Safety

- 20 ft. boom reach includes 4 ft. telescopic extension

- Large counter-weight and suspension locks add stability for loading

- Counterbalance valves on all boom cylinders for safety

Driving Suite

Driving suite includes steering wheel, brake and accelerator pedal, transmission controls, horn, windshield wipers, air ride seat, and accessory power. Option diagnostic screen available.

Operator Controls

Operator controls for loader, outriggers, and suspension locks.

Enclosed Cab

Enclosed cab with windows throughout (including roof) and full heat and A/C.

Improved Mobility

Steering axle to the rear during rear steer mode for maximum mobility and tight alleys.

Tandem Pump

Tandem pump for faster operation of multiple functions.

Suspension Locks

Suspension locks bypass leaf springs to allow a more stable platform when working without outriggers deployed.

Steel Counterweight

4″ steel counterweight allows the operator to load most debris without using the outriggers.

RUBBER TIRES (**) OUTRIGGERS EXTENDED

| RADIUS | OVER SIDE | OVER REAR | OVER SIDE | OVER REAR |

|---|---|---|---|---|

| 10 | 4290 lbs | 5475 lbs | 5916 lbs | 7960 lbs |

| 16 | 1789 lbs | 3053 lbs | 3026 lbs | 4960 lbs |

| 20 | 1433 lbs | 2560 lbs | 2261 lbs | 4100 lbs |

Notes:

Weight of attachment to be subtracted from lift capacities. Standard Trash bucket weighs 960 lbs.

Radii are measured in feet from the center of rotation to the center of the bucket.

Safe working load with outriggers extended and machine on firm level ground does not exceed 85% of vehicle tipping moment.

**Safe working load with outriggers retracted and machine on firm level ground does not exceed 75% of vehicle tipping moment.

General

| Reach (From Centerline Rotation) | 20 feet |

| Main Boom and Tip Boom | 16 feet |

| Tip Extension | 4 feet |

| Tare Weight (Empty) | 21,920 lbs |

| Front Axle Weight | 5,340 lbs |

| Rear Axle Weight | 16,580 lbs |

| Outrigger Span | 11’8″ |

| Storage Height | 11’6″ |

Bucket Features

All-purpose clamshell design, 4 feet wide with an opened width of 5 feet for large bites. High impact tempered steel used on bucket cutting edges for extended life. Reverse curve shape helps prevent scalping of lawns. Continuous rotation. No hoses below the bucket rotator.

Chassis Specification

| Body Style | Conventional Cab |

| Cab-to-Axle Dimension | 90″ |

| Front Axle Rating | 10,000 lbs |

| Rear Axle Rating | 21,000 lbs |

| Gross Vehicle Weight Rating | 31,000 lbs |

| Frame | 1,500,000 RBM |

| Engine | 210 HP Diesel |

| Transmission | World 3060P |

Performance

Productivity increased by not needing to stow bucket between route stops. Two six function mechanical joysticks reduce maintenance compared to traditional designs. Tandem pump allows multiple loader functions without power loss. When loading, travel speed is restricted. When traveling. loader movements are restricted.

Structural

A-frame pedestal design allows flexing under repeated load shocks. Replaceable Cast Nylon bushings used in head assembly. Head assembly is stress relieved. Reinforced connection points with hardened pins and replaceable bushings. Safety locking valves used on boom and outrigger cylinders.

Single Electronic Joystick

A single electronic joystick operates loader functions. These controls are also fully proportional and have preprogrammed ramp rates to reduce wear on loader.

Dual Mechanical Joysticks

Two mechanical joysticks operate loader functions. These controls are fully proportional; allowing for minute adjustments. Joysticks are connected to valve banks via mechanical linkages.

Dual Electronic Joysticks

Two electronic joysticks operate loader functions. These controls are fully proportional and have preprogrammed ramp rates to reduce wear on loader.