HL3 Hooklift Truck Mount Grapple Loader

Classic Muscle. Quick Versatility

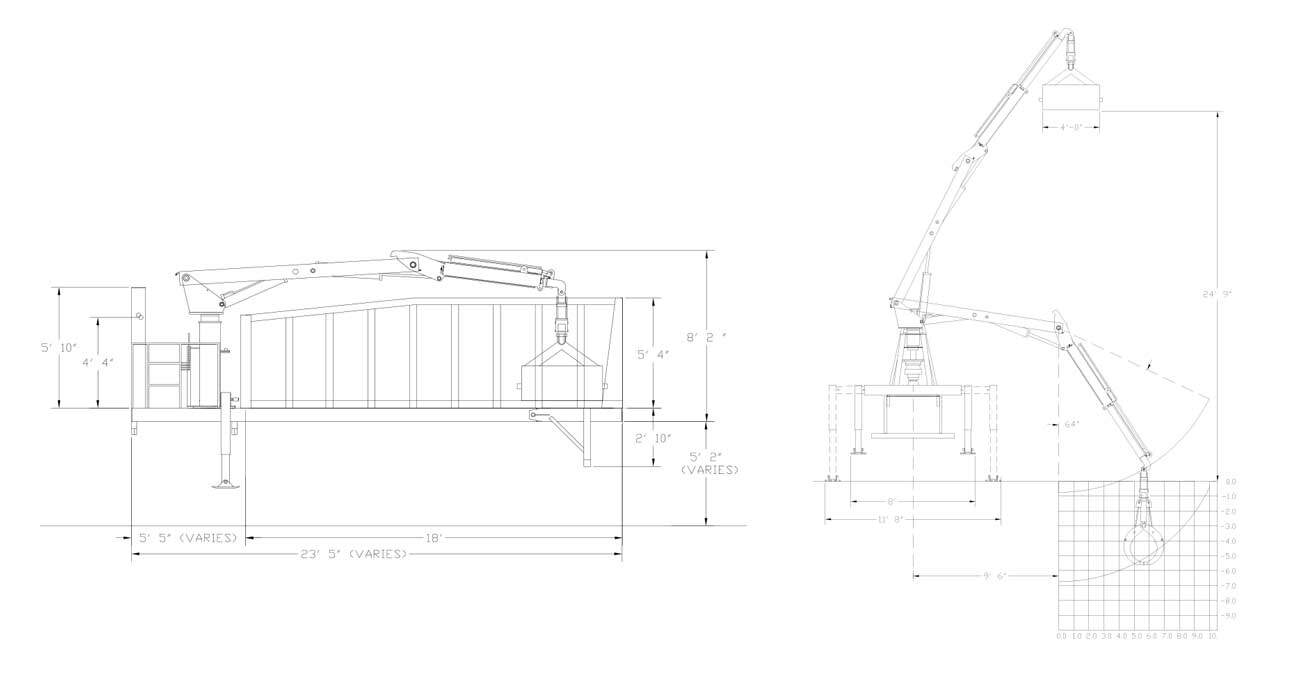

The Petersen HL3 Lightning Loader Hooklift Truck and 18 foot, 24 cubic yard body are mounted on a steel skid.

The heavy-duty bumper on the rear of the body and outriggers on the front of the body allow for easy installation and removal of the unit. The Grapple Loader is hydraulically locked to the chassis.

Petersen Industries HL3 Hooklift Truck Mount Grapple Loader Advantages

Make Your Fleet Versatile

Adding the HL3 Hooklift Skid to your fleet turns a container truck into a multipurpose unit.

- Loading muscle when you need it makes your fleet more versatile and allow you to handle the job that needs to be done.

- Easy installation and removal: Load the skid from inside the cab, then secure it with the hydraulic locking device

Endurance

In this industry, it’s not only about how many hits you can take, but about how long you can keep operating at peak performance. Our hooklift grapple loader offers:

- A state-of-the-art hydraulic and filtration system designed to keep this vital portion of the loader running as smoothly as possible.

- Turn your hooklift container truck into a multipurpose grapple loading machine.

CONTROL OPTIONS

Greaseless proportional dual walk-thru standard lever controls are operational from either side of the truck. Petersen also offers QUADSTICK® controls and stationary top mount controls with joysticks or valvehandles.

H-STYLE OUTRIGGERS

Horizontal and vertical outriggers act independently of each other. Allows the operator to custom place around obstructions and traffic patterns.

DUMP BODY

20’ 9” Loader & 18’, 24 cubic yard dump body mounted onto a steel skid.

GRIP FOR SAFETY

Grip strut, serrated steel walk platforms, steel handrails, and a frame lock control at the valve bank.

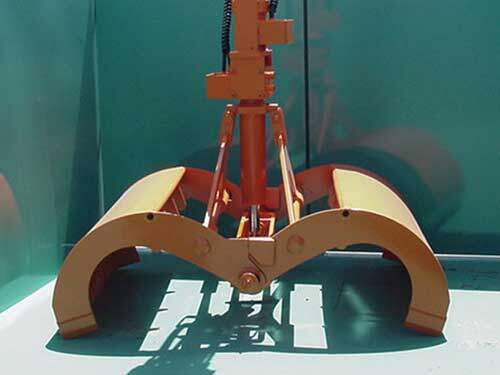

SINGLE CYLINDER BUCKET

A large cylinder and manifold block keep hoses out of work areas, allowing for a stronger bite force, and ensuring that both sides always work together.

STABLE BASE

Heavy-duty bumper on the rear and outriggers on the front of the body allow for easy installation and removal.

Hook Lift Truck System

| Reach (from centerline rotation) | 20 feet |

| Main Boom and Tip Boom | 16 feet |

| Tip Extension | 4 feet |

| Unit Weight (empty) | 12,700 lbs |

| Outrigger Span | 11 ‘8″ |

| Storage Height (above vehicle) | 8’4″ |

Lifting Capacity

| 10 Foot Radius | 7,100 lbs |

| 16 Foot Radius | 4,400 lbs |

| 20 Foot Radius | 3,200 lbs |

Weight of bucket and/or attachments must be subtracted from lift capacities shown. Standard bucket weighs appx. 1000 Ibs. Capacities shown do not exceed 85% of vehicle tipping moment with outriggers fully extended on firm, level ground.

Bucket Features

All purpose clamshell design, 4 feet wide with an opened width of 5 feet. Replaceable bolt-on bucket blades made of high impact tempered steel. Anti-scalping bucket sides are pivot mounted to provide a horizontal closing action rather than a vertical digging motion. Sides are mechanically linked to single hydraulic cylinder to ensure both sides close and open together. Continuous rotation. No hoses below bucket rotator.

Hook-Lift Truck Chassis & Hoist Requirements

The Petersen HL-3 loader system requires a heavy-duty chassis & hook-lift hoist. The complexity of the system and diversity of chassis/hoist combinations available necessitates that Petersen check each one individually prior to sale. The following are minimum requirements:

| 18ft, 24 cy | |

| GVW | 54,000 (tandem) |

| Cab to Trunion | 174 |

| Hoist Capacity | 32,000 lbs |

| Effective Length | 16ft 10in -17 ft 7in |

These are not complete chassis specifications. Call your Petersen representative about other possible chassis arrangements and for complete chassis specs

Trash Body

18 feet, 24 cubic yard capacity is standard size.

3/16 in solid plate floor on cross members with 12 in centers.

Operator Controls

Dual manual controls (greaseless) for outriggers and loader on both sides of truck for easy access and visibility. A “Grip Strut” serrated steel walk platform and steel handrail is included. Frame lock control lever is located at valve bank. Also available with QuadStick controls (mechanical six-function joysticks).

Structural

A-frame pedestal design allows flexing under repeated load shocks. Replaceable Cast Nylon Bushings used in head assembly. Head assembly is stress relieved. Reinforced connection points with hardened pins and replaceable bushings. Counterbalance valves used on all boom cylinders and pilot operated check valves used on vertical outrigger cylinders.

Dual Walk-Thru Controls

Greaseless dual controls are operator friendly and maintenance free!

Dual Controls: Control platform to be located directly behind conventional cab to allow operator access from the truck cab without ever having to touch the ground. A single bank of control valves to be mounted at the mid-point of loader, with control handles accessible from the operator platform on either side of truck. Control handle pattern must be the same on both sides of the truck for superior visibility. Control handles shall not require lubrication. A “Grip Strut” serrated steel walk platform is included.

QUADSTICK® Mechanical Controls

Completely mechanical! No high maintenance electronics!

Joystick (dual walk-thru): Petersen mechanical QUADSTICK® controls. Each of the four joysticks has six functions to control loader operation. Outriggers are controlled by two joysticks at the center of the operator platform. When applicable, body dump is controlled by a single lever at the center of the operator platform.

PATENT #7,353,652 B2

OUTRIGGER PADS

4x12x12 rubber pads mounted on bottoms of outrigger feet help prevent outriggers from causing damage to curbs etc.

ALL PURPOSE TRASH GRAPPLE

Petersen’s trash bucket is actuated by a single double-acting cylinder and capable of continuous rotation with no need for physical stops. The bucket motor, Model RE, has a 5,500 in. lbs. torque rating. Petersen buckets have the capability to be rolled over on the load without damage to any components, allowing for a maximum load while keeping boom height within acceptable limits. An anti-scalping feature is standard and advantageous for jobs requiring increased precision (ex: sidewalk removal).

The bucket also incorporates:

- 3/16″ plate, smooth steel clamshell scoop for leaves and sand

- End plates minimum of 5/8″ thick and of A-572 grade 50, 50,000 psi steel

- A minimum of 5 ribs per side to handle branches, logs and appliances

- A trample ram in the center for compressing trash in body.

- Replaceable bolt-on bucket blades made of high impact tempered steel

The bucket is 4 ft. long with an opened width of 5 ft. between pickup blades. Anti-scalping bucket sides are pivot mounted to provide a horizontal closing action rather than a vertical digging motion. Sides are mechanically linked to single hydraulic cylinder to ensure both sides close and open together. There are no hydraulic hoses located below bucket rotator.

HEAD-MOUNTED DUAL STROBES

Dual strobes mounted on the pedestal head.

HOSE GUARDS/SHIELDS

Metal guards cover the valve bank and back of head assembly to protect operator on walk-thru platform from hydraulic fluid in the case that there is a leak at these connection points.

Hose sleeves also available.

Only on walk-thru type controls.

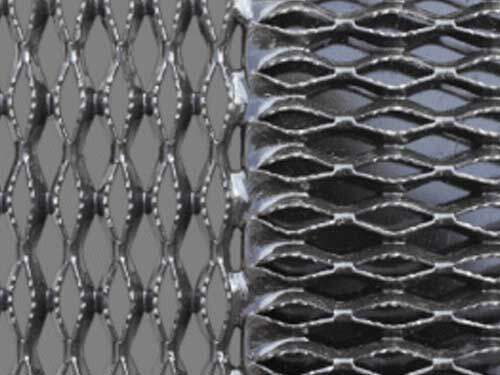

DOUBLE WIRE BRAIDED HOSE

3/8” 100R2 double wire braided hoses. 4,000 working pressure. 16,000 burst pressure.